首次三维成像提高镁合金强度的“孪晶”行为

近日,密西根大学的研究人员在一项旨在开发更轻质镁合金,以制造更省油、更经济的汽车研究中,利用强大的X射线首次捕捉到了合金三维图像的微观结构,研究团队发现这些微观结构有助于材料在不破裂的情况下吸收应力。

这项由美国能源部资助并发表在Science杂志上的研究成果,将有助于加深对此类合金在机械应力作用下复杂反应的理解。镁合金的重量比铝轻30%,如今,一些汽车制造商已开始将其用于非承重部件,但如果能优化其在受力情况下的表现,其应用范围将会大幅扩大。

每种金属的晶体结构,即原子高度有序且重复排列的结构,会影响其对压力的反应方式。汽车中最常用的两种金属钢和铝,在受到任何方向拉力时都能伸长,它们是通过所谓的滑移系统来实现这一功能的。在这个系统中,原子保持在各自的行内,但会在堆叠中移动以使列发生错位。滑移就像桌上的扑克牌,底部的牌保持不动,但对一侧施加的推力会使整个牌堆倾斜,因为每张牌都会比下面的那张移动得更远。

镁的晶体结构使得原子只能在少数几个方向上自由移动。当受到力的作用而无法沿这些方向移动时,镁合金就会形成“变形孪晶”,即晶体结构中相互镜像的部分,其通过改变某一区域原子的排列方向来实现。这可以类比为一张纸上的折页,当折页展开时,会形成一个倾斜的镜像部分。变形孪晶使材料能够在更多方向上伸展而不破裂,从而具备延展性,但当孪晶现象过度发展时,会导致缺陷集中,进而引发裂缝的形成。

密西根大学机械工程与材料科学与工程系助理教授、该研究的通讯作者Ashley Bucsek说道:“我们惊讶地发现,这三对孪晶都是在三叉交汇处形成的,即三块晶体相互接触的地方。而缺陷总是出现在孪晶与另一块晶体接触的部位。这种一致性有助于我们理解孪晶结构,从而优化材料的使用寿命。”

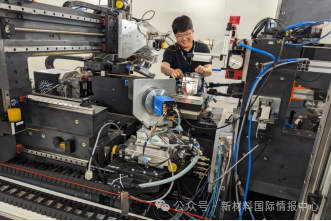

在实验开始前,研究人员使用了一台小型CT扫描仪来绘制出镁合金样本中晶体颗粒的排列方式。在此基础上,他们挑选出了一个具有良好排列方向的特定晶体颗粒,以便观察孪晶形成过程。

他们利用的是位于法国的欧洲同步辐射设施,这是全球少数几个能够产生足够强的X射线、以极高的分辨率成像所关注的物质颗粒且不破坏样本的设备之一。这种技术被称为暗场X射线显微镜技术,简称DXFM。其工作原理是让带电粒子在同步加速器中加速运动,并将它们发出的强X射线导向合金中。X射线会以不同的角度穿过晶体颗粒,这取决于这些颗粒的取向。这种“暗场”技术能够有选择地捕捉特定角度散射的X射线,在本例中,是选定相关的角度,然后通过一系列透镜放大散射X射线图像。

他们施加了三种典型的汽车零部件负载,这些负载会使合金产生伸长变形,分别为0.6兆帕、30兆帕和45兆帕,并在每次加载后都会对样品进行图像拍摄。密西根大学机械工程专业的博士生、该研究的首席作者Sangwon Lee表示:“在X射线图像中,我们得以近距离观察到应力作用下孪晶现象的发生过程。我们第一次亲眼目睹了孪晶结构的形成与演变。”这些高分辨率图像是实现材料延展性优化,同时不牺牲稳定性的第一步。接下来,研究团队计划实时捕捉相关变化。

3D Imaging Reveals How Twinning Boosts Magnesium Alloy Strength

In a study that advances lightweight magnesium alloys for more fuel-efficient, affordable vehicles, University of Michigan researchers used powerful X-rays to capture the first 3D views of the formation of microscopic structures that can help the material absorb stress without breaking.

The results, funded by the U.S. Department of Energy and published in Science, will improve understanding of the alloy's complex reaction to mechanical stress. Magnesium alloys weigh 30% less than aluminum. Today, some car manufacturers have started using them for nonload-bearing parts, but they could have much wider adoption if their behavior under stress can be optimized.

Each metal's crystalline structure—the highly ordered, repeating arrangement of atoms—influences how it responds to stress. Steel and aluminum, the most commonly used metals in cars, can stretch when pulled in any direction. They do this using what's referred to as slip systems, in which atoms stay in their row but shift in the stack to misalign the columns. Slipping is like a deck of cards on a table where the bottom card stays in place, but a push on one side makes the whole stack slant as each card moves a little further than the one below it.

Magnesium's crystalline structure only allows atoms to slip easily in a handful of directions. When pulled in directions it can't slip, magnesium alloys create "deformation twins"—mirror-image sections of the crystal structure—by shifting the orientation of atoms in a certain area. This can be thought of as an accordion fold in a sheet of paper, with the plane coming off the fold forming the mirror image at an angle.

Deformation twinning allows the material to stretch in more directions without breaking, creating ductility, but at a certain point too much twinning can create a concentration of defects that cause cracks to form.

"We were surprised to find all three twins formed in triple junctions, where three crystals touch, and defects always formed where the twin touches another crystal. This consistency can help us understand twin microstructures to optimize the material lifetime," said Ashley Bucsek, U-M assistant professor of mechanical engineering and materials science and engineering and corresponding author of the study.

Before the experiment, the researchers used a small-scale CT scanner to map how crystal grains were oriented within a magnesium alloy sample. From here, they selected a specific grain of interest with a good orientation for following the twinning process.

They leveraged the European Synchrotron Radiation Facility in France, one of a few facilities in the world able to generate powerful enough X-rays to image the grain of interest at an ultra-high resolution without destroying the sample.

The technique, called dark-field X-ray microscopy, or DXFM for short, works by accelerating charged particles around the synchrotron and directing the bright X-rays they emit into the alloy. X-rays diffract through the crystal grains at different angles depending on their orientation. The "dark field" technique selectively captures X-rays diffracted at a specific angle—in this case, the angle associated with the previously selected grain of interest—and magnifies the diffracted X-ray image using a series of lenses.

They applied three typical car part loads that would stretch the alloy—0.6 megapascals (MPa), a unit of tensile strength, 30 MPa and 45 MPa—imaging the sample between each.

"Real-space X-ray images gave us a front-row seat to observe twinning as stress was applied. We literally watched the twin appear and evolve with our own eyes for the first time," said Sangwon Lee, U-M doctoral student of mechanical engineering and lead author of the study.

The high-resolution images are the first step toward optimizing the material's ductility without compromising stability. As a next step, the research team plans to capture changes in real time.

More information:: Three-dimensional nucleation and growth of deformation twins in magnesium. Science(2025).

DOI: 10.1126/science.adv3460.

最新资讯

-

12-23

中国镁产量&榆林市镁产量(11月份)

-

12-23

Mysteel日报:硅铁期货窄幅震荡 个别报价涨价

-

12-23

Mysteel日报:镁价呈现坚挺 刚需成交为主

-

12-23

SMM尚镁网12.22日镁市场简评:镁市运行稳定

-

12-23

每日镁价(12.22)

-

12-23

镁市场:周初开市,镁价维稳运行

-

12-23

成本支撑边际修复 + 供应增速放缓下的止跌企稳格局

-

12-23

(12月15日—12月20日)资讯回顾

-

12-23

2025年12月19日镁报价及周评

-

12-22

每日镁价(12.19)

-

12-22

硅铁周评:稳中小幅挺涨 供需却是两弱

-

12-22

金属镁周评:先抑后扬回升 震荡风险犹存

-

12-22

Mysteel调研:硅铁盘面震荡 供应持续减量

-

12-22

Mysteel日报:硅铁震荡偏强运行 供应持续降低

-

12-22

Mysteel日报:原料底部企稳 镁价盘整运行

-

12-22

宜安科技公告:放弃控股子公司巢湖宜安云海科技有限公司部分股权转让优先购买权...

-

12-22

【SMM尚镁网一周镁市回顾】镁市周度分化明显 合金稳中独秀镁锭承压...

-

12-22

SMM尚镁网周评(12.15-19):镁市小幅回暖

-

12-22

榆林市:设立镁合金材料研发及产品试制中心,支持跨界应用场景突破...

-

12-22

明月湖实验室首席专家、副主任杨院生当选新西兰皇家科学院院士...

-

12-22

吉文金属 “高性价比镁合金板材在车身结构的应用” 项目获奖...

-

12-22

巢湖宜安云海科技获得某汽车主机零部件厂商镁合金重大项目定点,金额4.3亿元!...

-

12-22

镁市场简评:镁市温和回升

-

12-22

镁市呈现内强外稳格局 原料成本支撑下价格分化运行【SMM镁晨会纪要】...

-

12-22

宝武镁业:多材料协同发力 宝武集团为车企提供全套轻量化设计方案...

-

12-22

镁合金成材料产业升级核心方向 产业扩容催生上游原材料红利 镁锭硅铁迎增长窗口...

-

12-22

镁市周评(12.14~12.20)

-

12-20

2026 年中国镁产业发展趋势|轻量化刚需驱动 镁代铝元年启幕...

-

12-20

2025年1-11月中国共生产原镁约为91.74万吨

-

12-20

广汽获原联合多方成功研制半固态铸造镁合金

-

12-20

宜安科技子公司斩获4.3亿元镁合金汽车项目定点

-

12-20

山西银光华盛镁业高性能含稀土镁合金冶金质量调控关键技术与应用荣获 2024年度稀...

-

12-20

镁市回顾(12.15-12.19日)

-

12-20

府谷镁:区域品牌引领产业升级与县域经济高质量发展

-

12-20

辰致轻量化×天链机器人联合开发机器人镁合金电池盒